Welcome Swastik Technopack

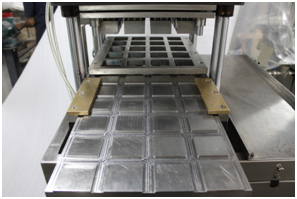

Operator will manually spread powder over the die such that the cavity of the die is fully filled with powder evenly Now the operator will bring the punch (male die part) down with the help of the lever, there is a sensor to adjust Maximum down stroke. Once reached, this will compress & compact loose powder in the shape of the die. Now the Operator takes the punch up by lever to a level where the punch & cavity die are separated by at least 50 mm. Now the operator must bring the tray forward by pressing the forward button, after the tray is forward and directly underneath the cavity die, the operator once again bring down the punch head by lever such that the tablets fall Onto the tray. Once the tablets are onto the tray, the operator again brings the punch head up by lever and then Press tray reverse button so that tray comes out and then keep another in its place & repeat the process.