Technical Specifications

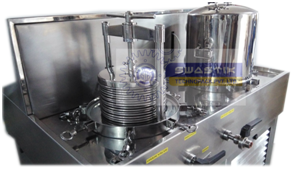

SAODMCIP2100

Salient Features

Power Required

380-440v/3 Ph/12kW

Compressor Auto Cut Off System

Air Required

NA

Flow Switch For Compressor Protection

Production Capacity

300 LPH

Preventive & Timer Circuit For Compressor

Approx. Dim. (LxWxH Mtrs.)

--

Single Unit Only (Indoor)

Approx. Weight (Kgs)

1500

Control Panel Non Flameproof

Manpower Required

1

High Level Low Level Trip Pre Fitted

Make Of Electrical Components

ABB/Bitzer

Temperature Gauges

Make Of Pneumatic Components

NA

Price

Make Of Electronic Components

Siemens/Schneider

Contact Us

Make Of Valves & Fittings

Cipriani/Inoxpa

Add Ons (For Pricing Contact Us)

Contact Parts MOC

SS 304L

Spare Kit (Recommended Add On)

Non Contact Parts MOC

SS 304

Copper Piping, Gasing & Testing (Req.)

No. Of Filter Plates

15

Integration With Auto Control Panel

Pre Fitted Paper Pad Filter Size

5 Microns

Change To PP Candle Type Filter

Inlet & Outlet Liquid Temp. Max.

20 & -4 Degrees C

--

Accepted Ambient Temp. Max.

22 Degrees C

--

Inlet & Outlet Size (Inch)

1.5 & 1

--